How does handle and spout get on the glass jug?

BlogWe have some glass jugs and carafes with handles and spouts in our range. You may have noticed that the handles and spouts of the carafes and glass jugs are not always quite identical, because like almost all of our glasses, these glass jugs and glass carafes are mouth-blown, the top rim and the spout are shaped by hand, and so is the handle.

Formen des Ausgießers/shaping of the rim and spout

Glas für den Henkel am Krug anheften/ glass is attached for the handle

Henkel wird geformt und befestigt/handle is shaped and attached

But now let’s start from the beginning:

The “Köbel” or “Ballot”

Glass production begins as usual. The “Kölbelmacher” takes a small glass amount from the melting pot and blows a small but very precise glass ball, this is the “Kölbel” or “Ballot”. It is important that the “Kölbel” is very precisely made, it must be the right size for the intended glass product and must not be crooked, as this would affect the finished product. This small glass sphere is then adjusted to approximately the later size by further glass removal with the glassmaker’s pipe from the melting pot.

A glassmaker then finishes blowing the glass in a wooden mould, with the upper part of the glass bubble hanging from the glassmaker’s pipe, a thin tube made of metal.

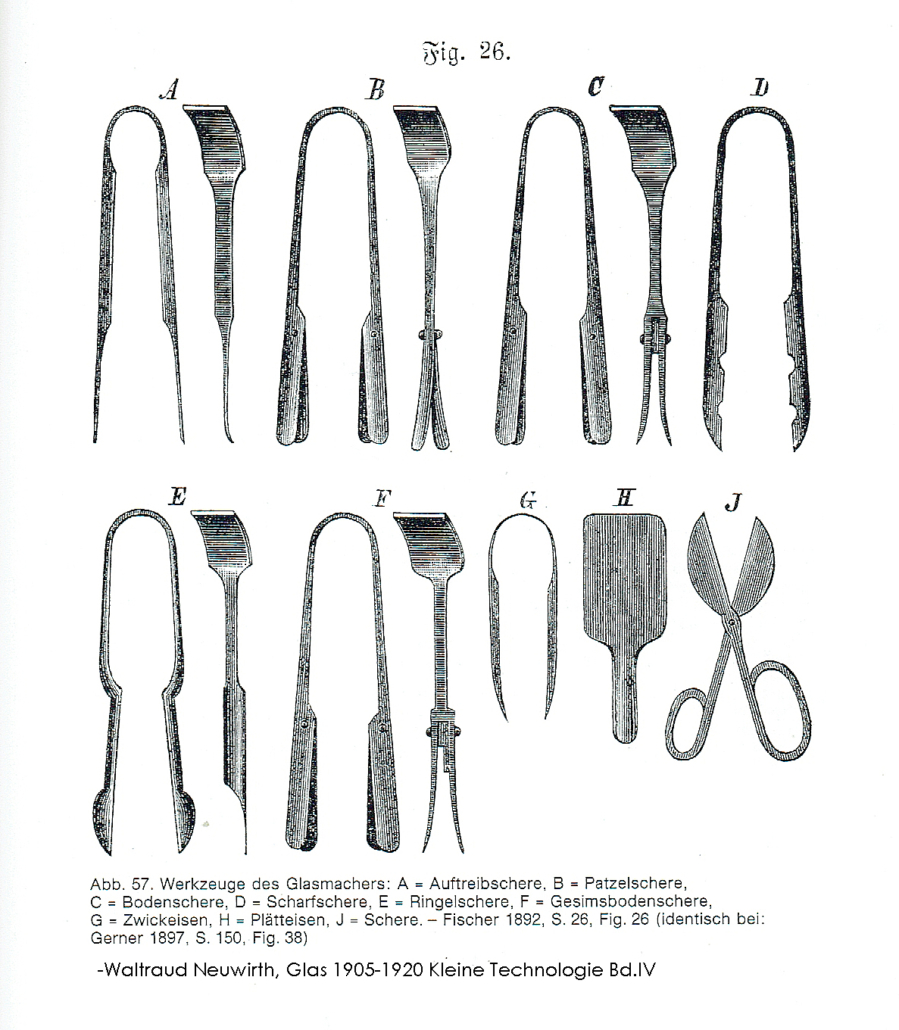

Next, the glass sphere has to be tacked down. Another glassmaker applies a tacking iron to the red-hot bottom of the glass body and the first glassmaker’s pipe is cut off. The master glassmaker cuts open the glass bubble. Then he shapes the rim of the jug open and forms the spout by hand and by eye using the simplest of metal tools.

This sounds easy, but it is all done in a red-hot state. The glassjug has to be warmed up again and again so that the temperature differences are not too great when the glass parts are joined together.

Attaching the handle to the glass jug

Now only the handle is missing on the glass jug. This is the work for the master craftsman. An assistant brings another lot of molten glass mass for the handle to the master, who attaches it to the red-hot workpiece. The handle is pulled into shape with the help of metal pliers and attached to the body of the glass jar. This is all done while the glass handle is red-hot and it’s done all by eye. The glassmaker has to accurately estimate the temperature of the glass body and the handle. If the difference in temperature is too great when the handle is attached to the glass jug, the glass will crack at the point where the handle is attached. This is called a “handle crack”. This is a typical processing error and should not occur. This is also a reason for complaint.

It takes a lot of experience to produce such glass objects in good quality and of course a well-rehearsed team of up to five glassmakers.

These techniques of glass making have developed over hundreds of years. We are happy and proud at the same time that we can still offer such glass.

Joh. Oertel & Co. Kristallglas

Petra Schütte

P.S. next: attaching and forming of a stem

OertelCrystal

OertelCrystal